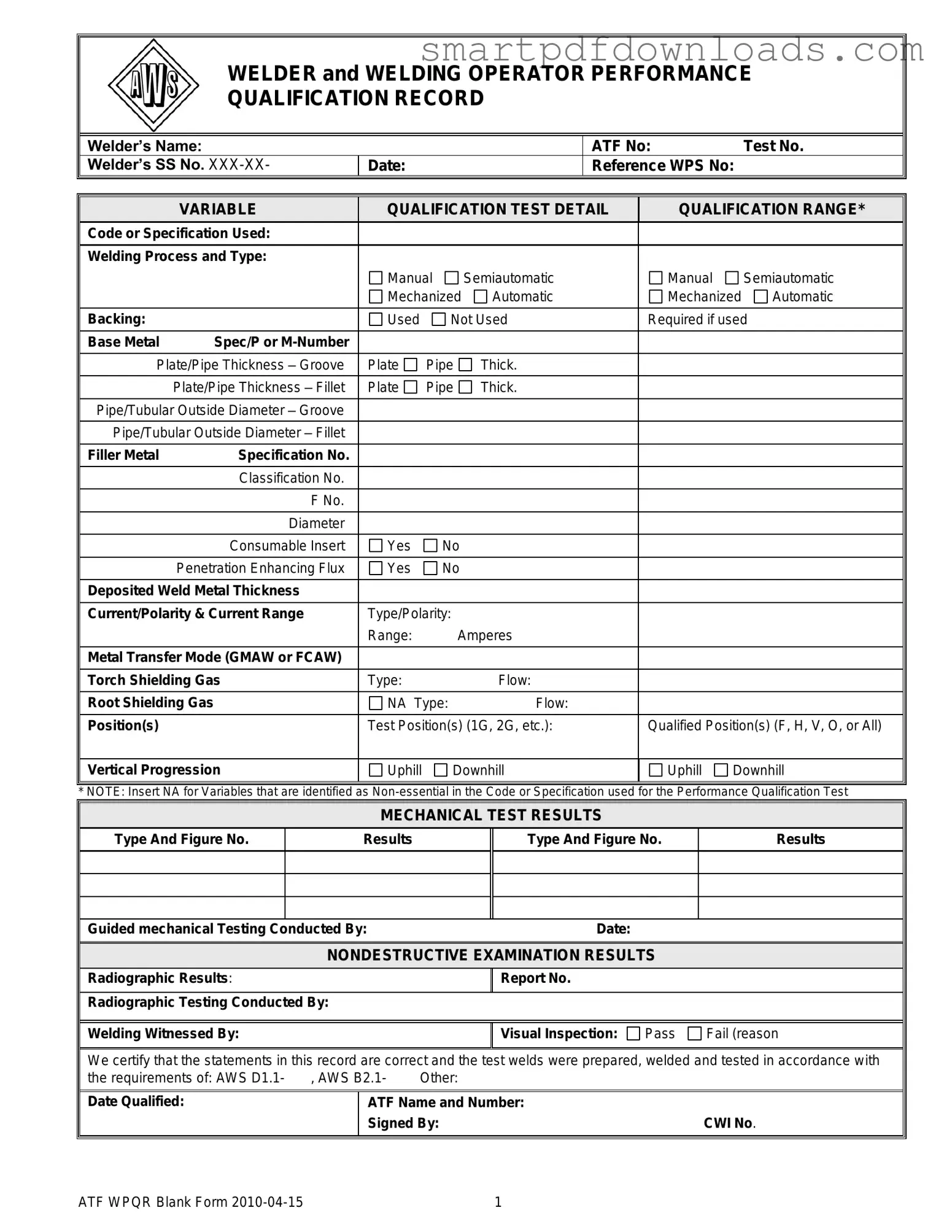

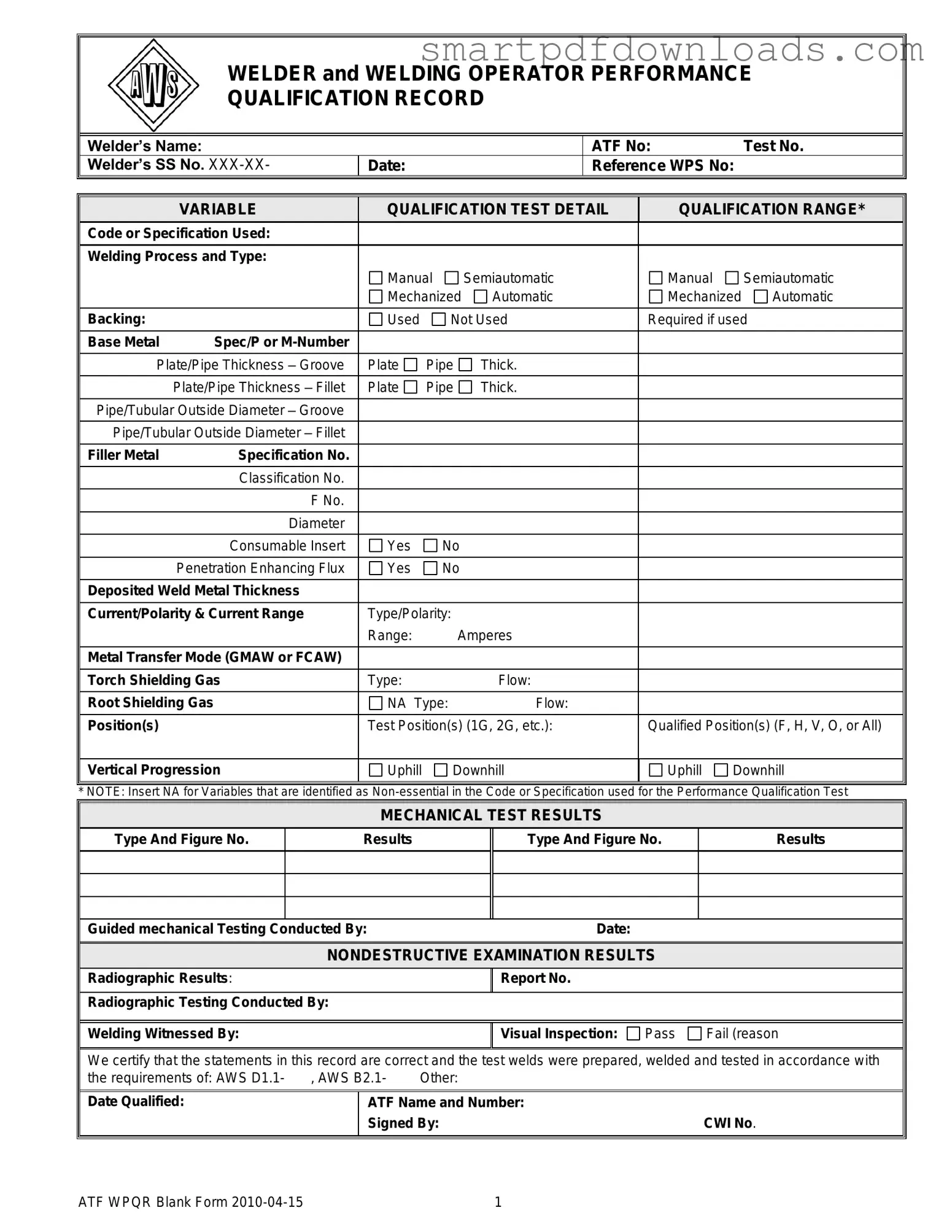

Welder Performance Qualification Record Form

The Welder Performance Qualification Record form is a critical document that verifies a welder's skills and qualifications. This form captures essential details about the welder, the tests they have completed, and the results of those tests. It serves as a formal record, ensuring that welders meet the necessary standards for various welding processes.

Edit Welder Performance Qualification Record Online

Welder Performance Qualification Record Form

Edit Welder Performance Qualification Record Online

Edit Welder Performance Qualification Record Online

or

⇓ PDF File

Finish the form and move on

Edit Welder Performance Qualification Record online fast, without printing.